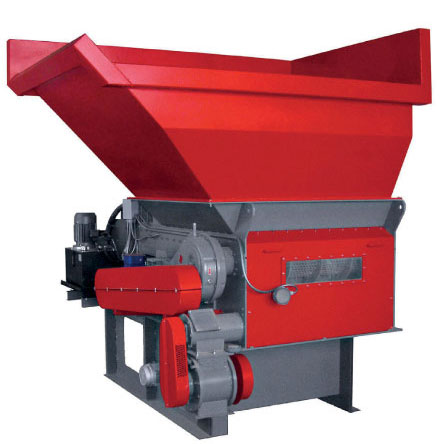

FIDA Shredder allows to shred waste wood, chipboard, pallets and crates. Material can be placed in bulk in the inlet hopper for grinding.

Rotor works at a low regime of rpm and is equipped with easy replacement tools.

MFO-40 SHREDDER

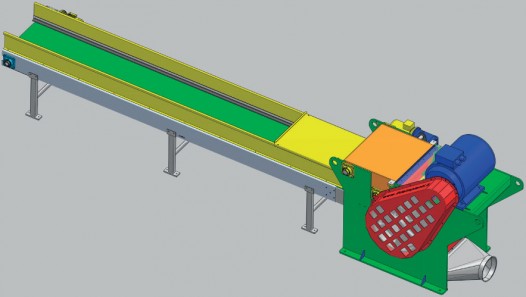

MFO-40 horizontally loaded shredder, suitable for panel saw wastes

FIDA shredder is able to grind wood wastes by a rotation low speed of the main rotor to maintain low the noise level and the energy consumption.

The machine is peculiar for its strong structure and a rotor made of a full round of special steel. Inside it, by mean of workings by special tools, we realise the basements of the knives.

Knives and counter-knife are made of tempered special steel with an high coefficient of hardness, able to treat even particular metals such as nails and staples. You can move easily the knives, turn them four times and finally substitute them few times a year, when you do the ordinary maintenance operations and according to the use of the machine.

You can put all the materials inside the top box without a previous classification. Then they are compacted by an hydraulic pusher and conveyed against the knives rotor.

The grinded material falls into the grid; here, the thinner chipped material goes down inside the suction cape while the biggest one come back the feeding mouth to be shredded again.

The hydraulic board which controls the cylinder and the pusher permits a two-speed movement, to optimize the hourly production and the energetic consumption.

The machine has got an electric panel to run automatically, by a PLC, all the grinding operations. The software is the result of an intensive activity of research aiming to optimize the efficiency of the shredder with respect to the material put inside.

Inside the suction pipe we put a magnet which must catch all the metallic particles. Then the shredder has got a convenient shutter for the periodic cleaning.